Automatic Collision Detection for Rotary Holes

The ability to automatically remove collisions has been extended when drilling rotary holes. Previously this was implemented for planar holes. Activated through the Update Fixtures command, the Hole cycle now avoids collisions with the fixture when drilling Rotary Holes, and a message is written to the Feedback window stating the number of holes that have not been machined.

EDGECAM 2023 B Axis Contouring Cycle Smoothing

Having listened to customer feedback, EDGECAM 2023.1 introduces a new modifier to the B Axis Contouring Cycle. Turners can now use the “Smoothing Factor” command to further control the B-Axis movements when profiling. Previously, the cycle could generate large movements on the linear axis and excessive fluctuations of the B-Axis (rotary) axes. This could lead to potential machine tool wear and poorer surface texture.

The ‘Smoothing Factor’ will dampen down the movements. Refining the NC Code by reducing the number of intermediate points in the toolpath.

Boss Offsets available in the Roughing Cycle

EDGECAM 2023.1 introduces new ‘Boss offsets’ in the Roughing Cycle.

Available for both solid model Features and wireframe geometry, the enhancement is specifically aimed at ‘nested pockets’ comprising of external bosses.

Users will save time by not having to create extra cycles with various offsets. Typical application would be on thin-walled pockets where a specific offset must be maintained but other features can have a different offset.

EDGECAM 2023 Chamfering and Rest Finishing Cycle Enhancements

Users will now discover that EDGECAM 2023.1 will more accurately support the ‘Optimise’ mill type strategy. Previously, a combination of Link strategy and component shape forced the toolpath to adopt a different strategy which inevitably led to a higher cycle time.

A further example of customer led enhancement request, is the support for Ballnose cutters when using the Chamfer Cycle. Previously the cycle only offered support for spot drills or taper tools. Customers feedback that on certain components, only a Ballnose generated chamfer would be accepted.

Finish Groove Cycle and Feature Finding Improvements

EDGECAM 2023.1 has improved its Turn Feature Finding capability when creating features from complex solid models. Previously, the resultant Feature could only be created by using a finer tolerance, but this incurred a longer time period to produce the feature.

Users will now discover that the same style models will instantly create features using a standard tolerance.

The Finish Groove Cycle has been enhanced so as users can now complete a groove feature with a grooving tool of the same width. Previously this would have been achievable by creating numerous CAM instructions which increased setup time.

EDGECAM 2023 Machine Tool Configurations

Reacting to the demands of the ever-changing machine tool builders world, EDGECAM 2023.1 enhances its support for six axes milling machines by now including a third rotary axis for both nutated and orthogonal configurations. Specifically, the release supports two axes in the rotary head plus one axis on a rotary table axis.

Simple 3+2 machining is supported as well complex 5-Axis simultaneous milling can be supported in all configurations.

Users will discover that both the “Select Rotary Axes” and “Move Index” commands have been enhanced to determine specific axis control.

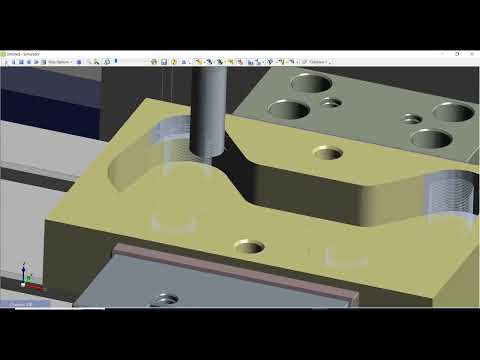

Waveform Roughing Cycle Performance Boost

Reducing calculation time by enhancing EDGECAM’s processing capability, has led to a productivity boost when working with the Waveform Roughing Cycle in EDGECAM 2023.1. Regardless of whether you are machining wireframe or solid models, the productivity gains can be as large as 40% faster.

Simply regenerate the toolpath and EDGECAM 2023.1 will do the work.

EDGECAM 2023 Rough Profile Cycle Disable Collision

EDGECAM 2023.1 introduces yet another time saving enhancement in the Turning environment. Users can now disable holder collision checking when using the Rough Profile Turning cycle.

Large components with complex tool holders, the calculation time can be overly long due to EDGECAM’s naturally stringent collision checking algorithm. Where the user feels the toolpath is already safe, the holder collision check can be removed thus boosting cycle time calculation.

EDGECAM 2023 Rough Turning Cycle SWARF Improvement

Led by frequent customer requests, EDGECAM 2023.1 has extended its support for the popular SWARF control function. Users can now influence the manner in which the toolpath moves to the ‘park position’ by freezing an axis. For example, on long turned shafts it is desirable to pull the tool away in only the X axis. Thus, the tool remains stationary in the Z axis producing a significant cycle time saving.